When the cool months draw in, there’s nothing quite like the crackling warmth from a wood stove. But as I navigate the complexities of maintaining such comforts, I am persistently reminded of the importance of selecting the best lining materials for log burner flue systems. Not only do they safeguard the chimney structure, but they also influence the efficiency and emissions of the burn. The pursuit of the right log burner flue lining materials might seem daunting, yet my experience as a professional dictates the necessity for a comprehensive guide and honest reviews.

The log burner flue lining materials comparison reveals a stark divergence in performance and suitability. From stainless steel to clay, each possesses unique attributes that can markedly impact the longevity and efficacy of a log burner’s flue. In my assessments, I strive to offer a clear delineation of these materials, aiding you in making an informed choice that harmonises with your specific heating needs. So, let’s delve into the details and discover which flue lining material reigns supreme for your wood stove.

Understanding the Significance of Flue Liners in Wood Stoves

As an adept home heating enthusiast, I’ve learnt that an efficient wood stove is only as good as its flue lining. The market is awash with log burner flue lining options, each claiming to enhance wood stove flue efficiency and ensure chimney safety. But with so many choices, it’s pivotal to understand their significance, function, and the materials that constitute the best log burner flue materials.

What is a Flue Liner and Why Is It Crucial for Efficient Stove Functioning?

My years of exploring various heating systems have affirmed that a flue liner is not just a mere accessory but an integral part of a chimney that safeguards against potential fire hazards. It operates as a conduit that channels combustion by-products to the atmosphere, all the while maintaining an optimal draft required for combustion.

The Role of Flue Liners in Chimney Safety and Heat Optimisation

Chimney fires — a dire threat that I’ve observed can be mitigated with a proper flue liner, one that contends with the by-products of burning wood, avoiding the build-up of flammable creosote. Not only does the flue liner preserve the masonry, it significantly reduces the amount of heat transfer to combustibles in the home.

Anatomy of a Flue Liner: Materials, Structure, and Performance

Having discussed various flue liners with professionals in the field, I’m enlightened to share that stainless steel and clay tile linings are prevalent due to their resilience and effectiveness. The right choice in log burner flue lining options is not an arbitrary decision but one dictated by the specifics of your wood stove, including its output and the type of fuel it burns. A well-considered liner contributes substantially to the wood stove’s efficiency, ensuring that you’re not just burning logs, but doing so in the safest and most efficient manner possible.

Best Lining Materials for Log Burner Flue

Identifying the best materials for log burner flue lining is paramount for the longevity and effective operation of your wood stove. Stainless steel flue liners emerge as a top contender, merging durability with efficiency. As I delve into the intricacies of selecting the appropriate flue lining materials, it’s clear that the grade of stainless steel and the correct flue diameter sizing play a crucial role in optimising wood stove function.

Stainless Steel Flue Liners: Durability Meets Efficiency

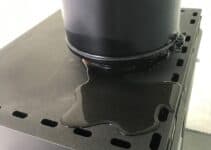

When it comes to lining materials for log burner flue, stainless steel flue liners stand out for their exceptional resistance to high temperatures and corrosion. A stainless steel flue ensures a strong draft, reduces build-up of creosote, and minimises the risk of chimney fires. Its adaptability for both new installations and upgrades to existing systems makes it a compelling choice for homeowners and professionals alike.

Comparing Stainless Steel Grades: 316 vs 904 for Log Burner Flue Linings

Let’s consider the two main grades of stainless steel used for flue liners: 316 stainless steel and 904 stainless steel. Each offers unique benefits according to the type of fuel burnt in the log burner. To provide clarity on the suitability of each grade for various users, I’ve prepared a comparison to aid in making an informed decision:

| Stainless Steel Grade | Best For | Corrosion Resistance | Fuel Type Compatibility |

|---|---|---|---|

| 316 | Dried seasoned wood, gas, oil | Good | Low sulphur coal |

| 904 | Diverse fuel usage, e.g., coke, peat | Excellent | Higher sulphur fuels |

Diameter and Sizing Requirements for Optimal Wood Stove Function

Flue diameter sizing is critical to ensure effective draw and combustion in the stove. As a rule of thumb, a 6” (150mm) flue diameter is adequate for stoves with an output of up to 20kW. This ensures the flue is not restricted, allowing for an efficient escape of gases. However, for DEFRA certified stoves, the manufacturer may specify a slightly smaller 5” (125mm) diameter, aligning with the stove’s design for cleaner burning. It’s vital to adhere to these diameter requirements for safety, performance, and regulatory compliance.

It’s my responsibility to offer factual guidance and facilitate a safe, efficient, and environmentally friendly use of log burners through proper selection and installation of flue liners. With the above information, I trust that you can choose the best materials for log burner flue lining that meet your specific needs while abiding by industry standards and sustainability practices.

Advancements in Flue Liner Installations

As a dedicated advocate for enhancing home safety and operational efficiency, I’ve observed how the evolution of chimney liners has led to substantial progress in the safety and functionality of chimney systems. Modern flue liner installations boast significant developments, with flexible liners and smooth-walled rigid options offering bespoke solutions, catering to various heating applications and improving overall system efficiency.

One of the most notable improvements has been the introduction of flexible chimney liners, which offer unprecedented manoeuvrability. This innovation enables a precise fit within uniquely structured chimneys, promoting easier installation and better conformity to safety standards. Simultaneously, smooth-walled rigid liners have become the preferred choice for their superior draught and easier cleaning, mainly when used with oil and gas appliances.

Further advancements in the realm of chimney liner improvement include the development of comprehensive all-in-one liner kits. These kits come equipped with vital components such as appliance connectors, roof termination and even a rain cap, effectively simplifying the installation process and shortening setup times. The presence of trusted providers such as DuraVent and Lifetime Chimney Liners ensures that the industry’s standards for stainless steel chimney systems are upheld, offering user-friendly products without compromising safety or quality.

- Increased versatility with flexible and rigid liner options

- User-friendly all-in-one liner kits for a streamlined installation process

- Quality assurance from reputable brands supplying high-grade stainless steel liners

However, the bedrock of installing a safe and adequate chimney system remains in understanding the specific fuel type used by the heating appliance. Properly sizing the liner is not a mere recommendation; it’s a necessity for ensuring the long-term safety of inhabitants and the optimal performance of the heating system.

Through the continuous improvement of materials and installation methods, domestic chimney systems have never been more reliable. Whether opting for stainless steel chimney systems or the more supple flexible chimney liners, the advancements in technology overwhelmingly contribute to a safer, more efficient home heating era.

Exploring Flue Liner Materials Beyond Stainless Steel

When I delve into the subject of log burner flue lining materials for sale, it’s clear that the industry extends well beyond just stainless steel options. There are tried-and-tested materials that have stood the test of time, as well as innovative solutions adapting to modern heating requirements.

Clay Tile Liners: Understanding Their Longevity and Limitations

Clay tile chimney liners have a storied history within masonry chimneys, well-regarded for their long lifespan and decent insulating properties. My installation experience suggests that while they are generally robust, they do present challenges when it comes to repairs, particularly if cracking occurs.

Cast-in-Place Liners: Weighing the Benefits of New Technologies

The adoption of cast-in-place chimney systems is on the rise, thanks to the structural integrity and insulation they provide. This method involves pouring a cement-like substance into the chimney to form a seamless liner, adapting flawlessly to the chimney’s dimensions and providing noteworthy durability.

Aluminium versus Steel Flue Liners: Applications and Appropriateness

Aluminium flue liners, predominantly chosen for specific gas appliances, offer a lightweight solution and are easier to handle during the installation process. Nevertheless, for multifuel use, where resilience and a broad application range are paramount, steel is the recommended material. It is worth noting that the equation varies depending on the heating appliance and the fuel used, each demanding a liner that is best suited for its specific characteristics.

In the market available today, the various chimney lining alternatives present a diverse tableau of options:

| Material Type | Primary Use | Pros | Cons |

|---|---|---|---|

| Clay Tile | Masonry chimneys | Durability, Good insulation | Difficult to repair |

| Cast-in-Place | Chimney refurbishment/upgrade | Structural integrity, Excellent insulation | Professional installation required |

| Aluminium | Selected gas appliances | Lightweight, Easy to install | Not suitable for solid fuels or high heat |

| Stainless Steel | Multifuel appliances | High durability, Resists corrosion | More expensive than aluminium |

Each material plays a significant role in the safety and functionality of a log burner. Choosing between them involves weighing factors such as longevity, installation ease, and the nature of the heating system. Investment in the right chimney liner not only safeguards against potential hazards but also enhances the heating efficacy of the appliance it serves.

Conclusion

In summarising this guide, I must stress the pivotal role the right flue lining material plays in enhancing a wood stove’s performance, safety, and longevity. Having sifted through log burner flue lining materials reviews and made thorough comparisons, I’ve discerned that stainless steel liners, particularly of grades 316 and 904, offer an optimal balance. Their resilience and cost-effectiveness are appealing to those invested in the endurance of their heating systems. Yet, one should not overlook the potential of alternative materials, which may align more closely with certain heating systems’ idiosyncratic demands and chimney architectures.

Moreover, keeping abreast of the latest innovations in flue liner installations can markedly improve the end-user’s experience. These advancements not only streamline the installation process but also meet the stringent criteria for safety standards, which must not be compromised under any circumstance. My comparisons have consistently highlighted the unmistakable wood stove flue lining benefits, ranging from increased heating efficiency to reduced hazard risks.

To conclude, my examination underscores the necessity of selecting a flue liner material that corresponds with your heating appliance’s fuel type, local environmental directives, and the personal weighing of upfront investment against long-term gains. This careful consideration will ensure a rewarding, enduring experience with your wood stove, whether you’re nestled in the frosty peaks of the Scottish Highlands or enjoying the rural serenity of the Cotswolds.